Recent Projects

Proven Expertise in Action

Explore our portfolio of successful projects across industries, showcasing the tailored solutions, skilled teams, and results-driven approach that make Waymaker Resource Group a trusted partner.

Holtec - Palisades

Project Support

WRG provided staff augmentation for professional staffing of Project Management, Project Controls, Scheduling, CMMS Integration SMEs, Licensing, Engineering and other professional staff. Project was able to scale to meet 6-10x initial request for personnel. WRG implemented strategic candidate sourcing, vetting, and customer integrated process flow to allow for efficient execution from time of need to time of deployment.

Nawah Nuclear

Core Offering: ER/Maintenance

WRG was contracted to develop formal bid offering, cost and Estimate at Complete (EAC) through provision of turn-key project management services, staffing and technical advisory support to research and develop long-term maintenance program elements within the Configuration Management & Maintenance System (CMMS) environment for all 4 units at Baraka Nuclear Station. WRG deployed a combined remote and on-site team of 40+ project managers, maintenance planners, P6 schedulers, financial analysts and controllers, procedure writers and HR/Onboarding personnel to support development of ~80,000 model work orders and maintenance work instructions, procedures and documentation to meet the requirements of 10CFR50, Appendix B nuclear quality assurance and the requirements of EPRI standards.

Lackland Air Force Base

Crane Inspection, Repair, and Procurement

WRG performed complete OSHA and CMAA inspections and load testing of 30+ overhead lifting devices and cranes, including specialty lifting devices specific to aircraft.

Hanford Waste Management - DOE

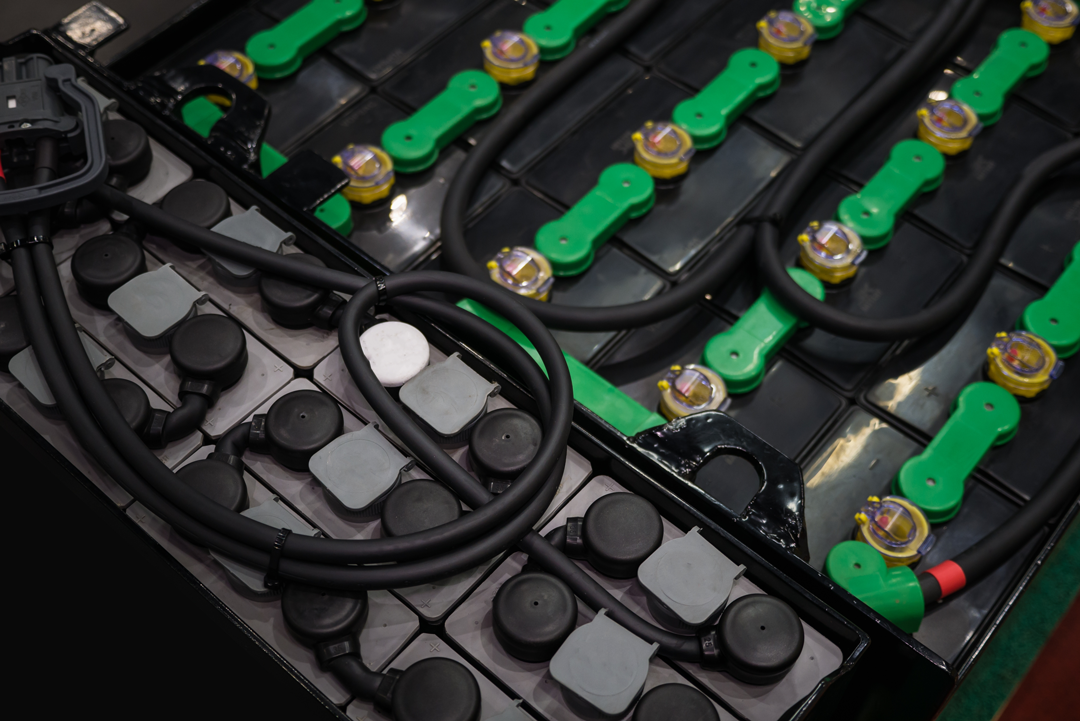

Crane Inspection and Refurbishment to CMAA standards

In this unique refurbishment scope, WRG implemented its Integrated Project Delivery (IPD) to perform the assessment of material condition, maintenance and repair of two 5T overhead cranes within the overall project that included shipping of the two cranes to WRG’s partner crane and large fabrication facility in Minnesota. WRG team members conducted an assessment to ASME and CMMA standard compliance of noted deficiencies and proposed recommended repairs to return the cranes to full operational status. Technical scope of work involved new motors, panels, electrical layout, weld assessment and repair. A new Factory Acceptance Test (FAT) was developed by WRG and performed. All project activities were performed within WRG's Quality Management Program (QMP).

Hanford Waste Management - DOE

ER/PMO/FEG Scheduling

WRG executed this Equipment Reliability, Preventive Maintenance Optimization, and Functional Equipment Group (ER/PMO/FEG) project with a combined remote and on-site team of 24+ project managers, schedulers, controllers, quality personnel and planners. This team developed Preventative Maintenance basis, Functional Equipment Groups and Systems and an integrated Long-Term Life-Cycle and Scheduling plan over a 10-year period with full integration into existing T-Week process in coordination with development of optimization adjustments. Within this effort, WRG lead project and technical personnel conducted weekly development, review and mentoring sessions with the Hanford engineering, maintenance, planning and program owner personnel. At project completion, over 60,000 components were assembled into FEG categories with PM's reviewed and optimized to prevent equipment or system failures.

JBER Air Force Base

Crane Inspection, Repair, and Procurement

WRG delivered maintenance and reliability program elements of inspection, maintenance, load testing and repair & modification for the total installed system cranes, hoists, lifts and supporting equipment for two (2) discreet air base installations. Scope of work is delivered through the WRG network of key partners, of which two exist in the State of Alaska specific to this technical capability. The total asset fleet under management is 150+ unique ID pieces of equipment and is compliant to the requirements and specifications for the Department of Defense, OSHA and crane and hoist specific standard of CMMA-70. Through fully remote project management and maintenance program oversight, the full scope of work is identified, scheduled and managed by the WRG remote office in coordination with JBER-stationed procurement and scheduling officers and the WRG technical service providers in Anchorage and includes development, quality review, transmittal and archiving of inspection, test and maintenance reporting.

Fort Peck Hydro - USACE

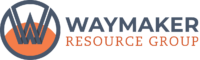

DC Battery and Charger Complete Replacement

WRG performed the Integrated Project Delivery (IPD) strategy, project management, and full project scope of replacement for two new 125V DC VLRA battery banks which included IEEE testing and certification. The project also consisted of the procurement and installation of four Battery Chargers for FP Powerplant#1 and Powerplant#2, as well as the UPS battery charger system. Completion of this project assures reliable asset management and resilient DC power system availability for our end customer.

Minot Air Force Base

UPS Procurement and Installation

WRG performed the Integrated Project Delivery (IPD) strategy, project management, and full project scope of replacement for the obsolete Uninterrupted Power Supply (UPS) for Minuteman Missile technology. This unique application required a nuclear certified UPS with replacement batteries in Building 546 within the Nuclear Codes Vault. Nuclear weapon systems must be certified prior to initial operational capability. Individual critical components/software must be operationally certified using OPCERT procedures prior to operational use. These procedures are used to determine if the critical components continue to meet the nuclear safety certification criteria identified when the weapon system was certified. WRG performed the procurement, installation, testing startup and turnover of this mission-critical UPS.

Holtec - Palisades

Project Controls and Program Management

WRG performed the Integrated Project Delivery (IPD) strategy, project management, and turnover of the Earned Value Management System (EVMS) for Holtec-Palisades site to align with DOE 913 EVMS reporting criteria. This project consisted of three specific deliverables: 1) Project Management Administration Processes, 2) Performance Indicators for Progress Reporting, and 3) Integrated Reporting Methods with examples to meet anticipated governance.

Energy Solutions Client / Accelerant Solutions delivery partner

Project Controls and Program Management

WRG contracted to provide long range decommissioning and deconstruction program effectiveness assessments to identify gaps and misalignment across all D&D projects and corporate programs developed as offered capabilities from Energy Solutions, but specifically for Kewaunee and Three Mile Island NPP’s. Scope included comparative analysis of 7 business unit-level programs, process and procedures toward development of standardized corporate program as well as risk-exposures in compliance to requirements at the Federal level within the Nuclear Regulatory Commission. In total, 125+ program elements were analyzed with opportunity to compile to a single hierarchy of program documents and deliverable in a range of 80-90 program elements. Scope was further expanded to develop a data environment to manage and track all processes of newly developed value stream phases and stage gates, which was achieved using existing enterprise platforms and integrated with advanced capabilities within MS-VISIO, including ‘hot links to the controlled document archive. Utilization of the dynamic process and value stream maps with 'hot links' process procedures and forms allows for live display at a nuclear facility in an 'Outage Control Center', 'Issues Resolution Room', 'War Rooms' or other control-room type environment for broad management review and challenges.

Southern Company - Vogtle Nuclear Power Plant

Outage Management and Outage Control Room Conduct Mentoring (New outage manager indoctrination)

WRG provided remote and onsite Subject Matter Expertise in development and performance of outage management, outage control room and overall outage schedule protocols and methods aligned with industry documents and best practices published by INPO, EPRI and WANO. WRG staff provided independent assessment, advisory support and in-person coaching and mentoring of the in-situ program and processes compared to day-to-day field and program activities in advance of refueling outage preparations. Work windows, outage windows and integration with broad On-Line work management principles were also evaluated for rigor in construct and application by the organization. WRG staff supported the client during all pre-outage milestone preparations and transitioned to in-field oversight and mentorship during execution of the outage.

Idaho Nuclear Technology Center - DOE

Project Controls and Program Management

WRG provided long range spent fuel storage and processing facility and operational value stream mapping over a 50+ year period timeline. The scope included performing program effectiveness assessments to identify gaps and misalignment across all facility stakeholder areas of accountability and corporate programs aligned with the requirements of the Nuclear Regulatory Commission. The project was identified as a ‘critical recovery effort’ driven primarily by internal KPI’s related to Estimate at Completion and increased oversight by the NRC / DOE related to budget overruns and project progress. WRG's primary focus was development of process, procedure and cost forecasting through end-of-life of facility in the 2050-2060 timeframe. In total, 19 discreet nuclear fuel storage, processing and long-term elimination processes and facilities were evaluated against forecasted cost to complete their functional duty and remaining budget allocations. WRG provided comprehensive cost management tools populated subcategory elements which were captured and housed at the corporate project management organization, accessible in a fully remote architecture utilizing ‘hot links’ to document and informational archives. Included in the deliverables was an advanced capability MS-VISIO enterprise value stream environment.

Lawrence Berkley Nuclear Laboratory - DOE

Project and Outage Management

WRG provided a long-range maintenance program focused on Life-Cycle management, preventative, predictive and outage / turn-around project process, procedures, planning, and scheduling. Included in this were evaluations of 40+ established procedures and processes as well as current work management and maintenance conduct of facility personnel and departments. WRG project personnel attended standing work planning and construction project planning meetings as direct support of the Maintenance and Outage Management in the roles of contracted technical advisors. Through this effort, 4 executive level program documents were developed which included a standard 36-mo cycle schedule and 28 core milestones of which all work activities would be governed. Within this, a dedicated risk analysis matrix and criticality point system was created to enable the facility to promptly assign work to be completed from a risk-informed approach. WRG provided new program training and assessment for pre-implementation efforts.

Entergy - Sarens, Williams

Project Support

WRG provided project support and administration services as commercial intermediary with responsibility for project cost and profit management in support of Master Service Agreements held by SARENS and Williams Power Services for long-term outage and non-outage maintenance and construction projects. WRG was added to the Tier 1 ‘Preferred Supplier’ approved supplier list with Entergy Corporate, completing a 30-day technical and safety assessment evaluation process through endorsement of SARENS.

Since that time, WRG has received the award for Safety and Diversity Leadership.

National Renewable Energy Laboratory (NREL) - DOE

Crane Inspection, Repair, and Procurement

WRG performed as was the prime contractor on this project overseeing full maintenance program for all inspection, testing, and maintenance of lifting devices and components, including electrical equipment & testing along with overall schedule management of over 700+ items across multiple facilities, testing bays, and campuses. This important scope was coordinated amongst multiple research facility schedule during operation to ensure no research was disturbed. Final reports were provided outlining and developing options for repair and remediation if any of the 700+ items were non-compliant.

Fort Wainwright Cranes and Hoists - DOD

Crane Inspection, Repair, and Procurement

WRG performed the full inspection and follow on services for all 54 cranes and hoists concurrent with inspection, testing, and certification cycle. Certify each crane and hoist in accordance with 29 CFR 1910.179. Preventative maintenance includes the lubrication of all moving parts, guide rails, track assemblies and components, cabling, hook assemblies, and the minor adjustment of limit switches, sensors, braking systems, safety systems, control push buttons, remote control units, etc. if needed within OEM guidelines. Repair cranes and hoists as necessary to keep them fully operational and to maintain their certification. Upon notification of a crane or hoist service requirement, 7 business days to respond on-site, with appropriate materials, tools, equipment, and personnel. Cranes and hoists were repaired and returned to service, including certification and load testing certificate (if required following structural repair).

Hanford HLW – 6T Canister Crane – DOE

New Crane Procurement

WRG is performing the Integrated Project Delivery for the fabrication, testing, and installation oversight for a new 6T single girder overhead crane. This crane project will include a full set of OEM drawings, operation and maintenance manuals, installation manuals, spare parts – in addition to the full fabrication testing, UL certification and testing of this new crane.

Hanford HLW – Electrical Cable Supply – DOE

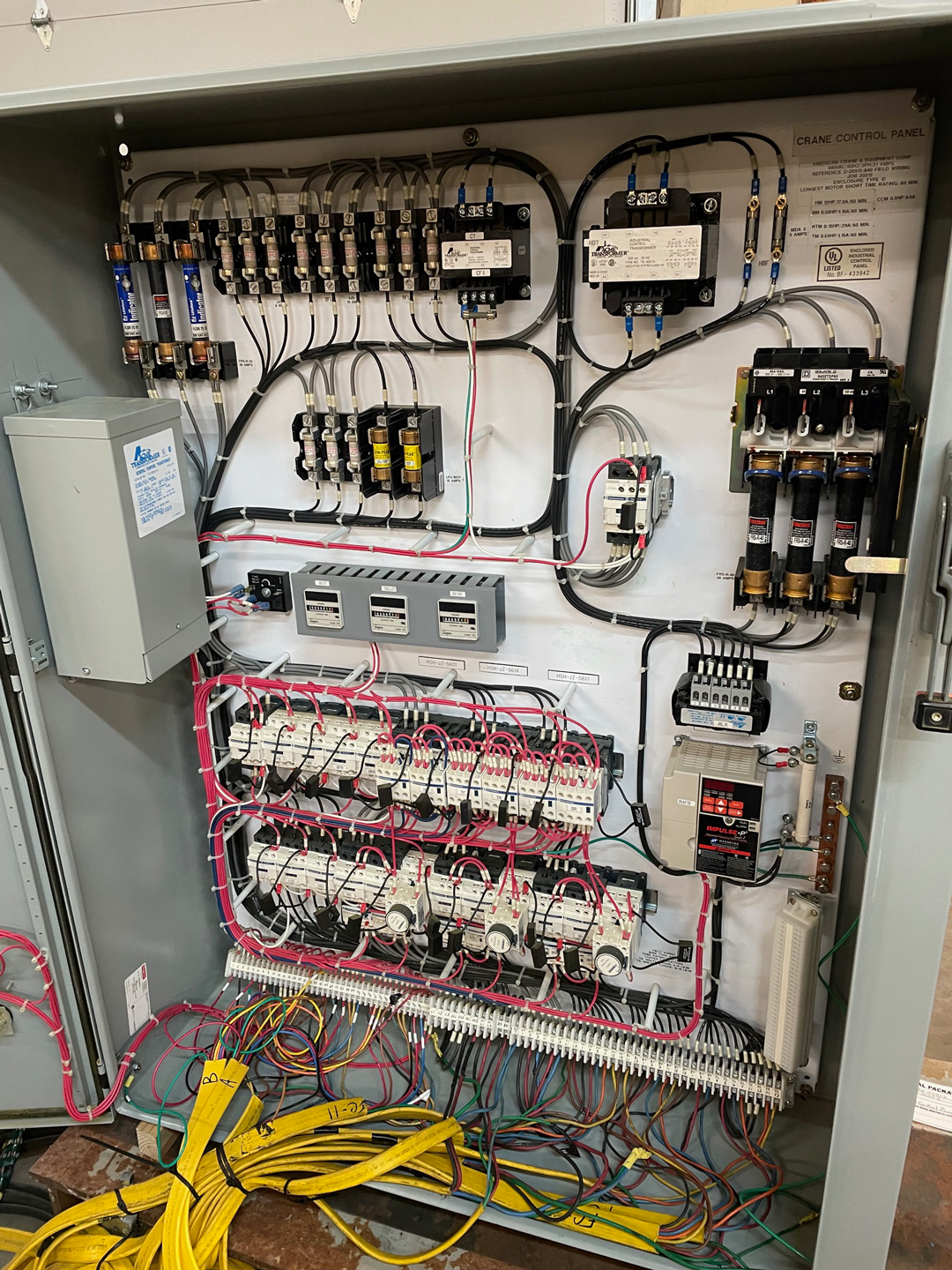

Electrical Procurement

WRG is performing the Integrated Project Delivery for the procurement, validation of specification requirements, and delivery of over 190+ various types of power and control cables. This project is expected to span over the project cycle of the customers’ overall facility completion project.

National Renewable Energy Laboratory – NREL – DOE

Electrical Maintenance and Testing

WRG is performing the Integrated Project Delivery for breaker and electrical system maintenance and testing. This project involves critical outage planning and scheduling such that there is no interruption to day-to-day operations to complete this activity. Various circuit breakers, power transformers and other electrical bus and distribution components are within scope. This project is expected to span over the project cycle of the customers’ overall facility completion project.

North Winds Test LLC

Project Controls and Management – Staff Augmentation

WRG is performing the Project Management and Controls for an integrated project supporting the Department of Defense. Project consists of detailed scheduling and integration of project controls in support of NorthWind LLC’s facility build.

X Energy

Procurement

WRG performed a specialty nuclear and balance of plant component and system supplier base audit and assessment to identify opportunities for optimization and risk to quality requirements being maintained through procurement process. Developed corrective actions for findings and mitigation and implementation action plan to resolve.

This project consisted of conducting in-depth assessment of corporate procurement and purchasing program process, procedures and implementing standards. Evaluated program documentation to industry standards for nuclear and commercial materials, components and equipment to ensure minimal risk to industry and client standards and requirement compliance. From this assessment, WRG developed a gap closure plan which resulted in the full suite of procurement and purchasing procedures, forms and instructions to be written, of which, all were completed by the contracted subject matter expert. Resulted in standard process and methodology for evaluation of supplier performance and validation of standard process for all procurement and purchasing activities supporting the deployment of the X Energy Small Modular Reactor Design (XE-100 product line).

Sargent/Lundy with Xcel Energy

Engineering Design Basis Assessment

WRG supported Xcel Energy’s implementation of a Risk Informed Engineering Program (RIEP) process in accordance with 10 CFR 50.69. WRG served in this capacity as a subcontractor to Sargent & Lundy, Xcel’s prime engineering vendor. WRG provided a team to perform strategic engineering reviews and provide comments for four of these SCDs. These vertical reviews were thorough design basis reviews of the assumptions, analysis and conclusions for the four identified systems. WRG included in its review utilization of the industry guidance which included NRC regulation, as well as the EPRI 10 CFR 50.69 Categorization Guidance Document (2018 Technical Report), NEI 00-04, NEI 16-09, and NEI 17-05. Review of each SCD included evaluation of the System Boundary and Components determination (including Key Safety Function identification and mapping system components to system functions), Passive Categorization, Probabilistic Risk Assessment Categorization, Defense-In-Depth Categorization, Preliminary Integrated Categorization and Qualitative.